適正なペレット化性能のためにペレットミール・マースをどのように選ぶか

2025-12-29

.gtr-pellet-dies-comp-9876 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 20px;

max-width: 100%;

box-sizing: border-box;

}

.gtr-pellet-dies-comp-9876 .gtr-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 20px;

color: #0056b3;

text-align: left;

}

.gtr-pellet-dies-comp-9876 .gtr-section-title {

font-size: 18px;

font-weight: bold;

margin-top: 30px;

margin-bottom: 15px;

color: #0056b3;

text-align: left;

border-bottom: 1px solid #eee;

padding-bottom: 5px;

}

.gtr-pellet-dies-comp-9876 p {

font-size: 14px;

margin-bottom: 15px;

text-align: left !important;

word-break: normal;

overflow-wrap: normal;

}

.gtr-pellet-dies-comp-9876 p strong {

color: #0056b3;

}

.gtr-pellet-dies-comp-9876 ul {

list-style: none !important;

padding-left: 20px !important;

margin-bottom: 15px;

}

.gtr-pellet-dies-comp-9876 ul li {

position: relative;

padding-left: 20px;

margin-bottom: 8px;

font-size: 14px;

text-align: left;

list-style: none !important;

}

.gtr-pellet-dies-comp-9876 ul li::before {

content: "•" !important;

position: absolute !important;

left: 0 !important;

color: #0056b3;

font-size: 18px;

line-height: 1;

top: 0;

}

.gtr-pellet-dies-comp-9876 ul li strong {

color: #0056b3;

list-style: none !important;

}

.gtr-pellet-dies-comp-9876 .gtr-contact-info {

font-size: 14px;

margin-top: 20px;

text-align: left !important;

}

.gtr-pellet-dies-comp-9876 .gtr-contact-info a {

color: #0056b3;

text-decoration: none;

}

.gtr-pellet-dies-comp-9876 .gtr-contact-info a:hover {

text-decoration: underline;

}

@media (min-width: 768px) {

.gtr-pellet-dies-comp-9876 {

padding: 30px 40px;

max-width: 900px;

margin: 0 auto;

}

.gtr-pellet-dies-comp-9876 .gtr-title {

font-size: 18px;

margin-bottom: 25px;

}

.gtr-pellet-dies-comp-9876 .gtr-section-title {

font-size: 18px;

margin-top: 40px;

margin-bottom: 20px;

}

.gtr-pellet-dies-comp-9876 p {

margin-bottom: 20px;

}

.gtr-pellet-dies-comp-9876 ul {

padding-left: 25px !important;

}

.gtr-pellet-dies-comp-9876 ul li {

padding-left: 25px;

margin-bottom: 10px;

}

.gtr-pellet-dies-comp-9876 ul li::before {

font-size: 20px;

}

}

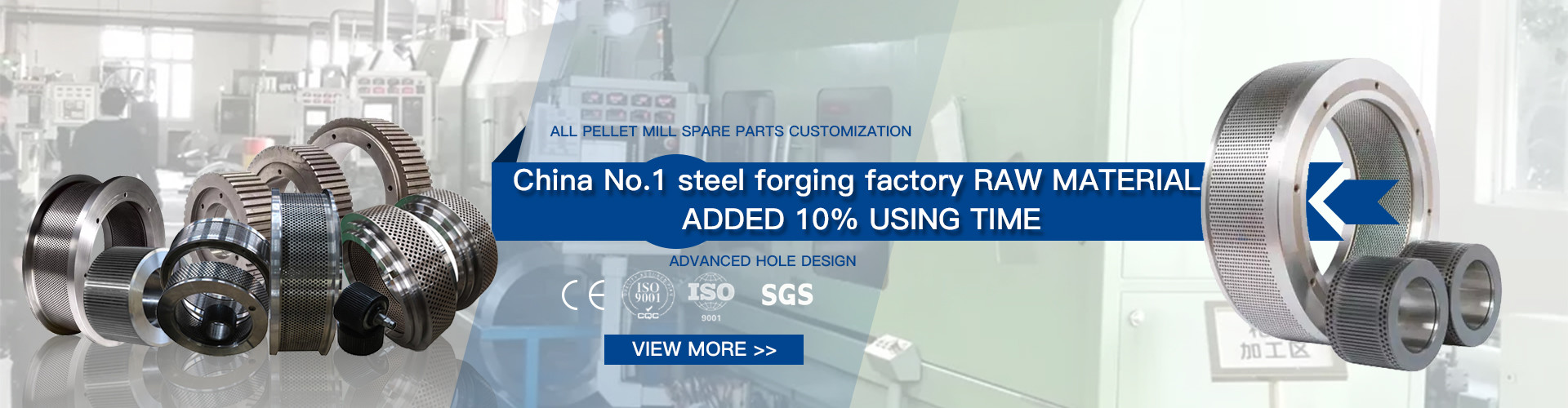

最適なペレット化性能を実現する高品質ペレットミルダイ

高性能ペレットミルダイの大手メーカーとして、CPM、SZLH、PTN、Bühlerなどの主要なペレットミルブランドに対応するカスタムおよび標準ペレットダイの製造を専門としています。 飼料、バイオマス、有機肥料の製造に関わらず、当社のペレットダイは、最大の効率性、耐久性、一貫性を実現するように設計されています。

ペレットミルダイとは?

ペレットミルダイは、ペレット化プロセスにおける重要なコンポーネントです。 粉末状の材料を圧縮し、均一なペレットに成形するための穴が開いた精密に設計されたリングまたはフラットプレートです。 ダイは、ローラーと連携して圧力と熱を加え、輸送、保管、給餌に最適な、コンパクトで高密度のペレットを形成します。

当社のペレットダイの能力

最適な互換性と性能を確保するために、正確な仕様に合わせてダイを製造する設備が整っています。 当社の能力には以下が含まれます:

カスタム製造(図面またはサンプルに基づく)

主要なペレットミルモデル用の標準ダイ

材料の選択(例:ステンレス鋼、合金鋼)

1.0 mmから12.0 mmまでのボアホールサイズ

お客様の原料と用途に合わせた圧縮比

対応ペレットミルブランド

CPM

SZLH

PTN

Bühler

およびその他の人気のある国際ブランド

すべてのダイは、寸法精度、硬度、表面仕上げについて完全にテストおよび検査されています。

当社のペレットダイを選ぶ理由

精密エンジニアリング:CNC機械加工されたダイは、高い出力と一貫したペレット品質を保証します。

カスタムソリューション:さまざまな原料(トウモロコシ、アルファルファ、小麦ふすまなど)に対応する、カスタマイズされた圧縮比と材料。

長寿命:耐摩耗性材料で作られ、耐久性のために熱処理されています。

短納期:世界中へのタイムリーな配送のための効率的な生産とロジスティクス。

技術サポート:ダイの選択とペレットミルの最適化に関する専門家によるコンサルティング。

用途

当社のペレットダイは、以下で広く使用されています:

飼料生産(家禽、牛、羊、魚)

バイオマスペレット化(木材、わら、もみ殻など)

有機肥料ペレット

産業および農業廃棄物ペレット化

今すぐお問い合わせください

信頼性の高い高性能ペレットミルダイをお探しですか? カスタムソリューションと比類のない品質のために、当社と提携してください。 サンプル、図面、または仕様をお送りください。お客様のニーズに完全に適合するダイを製造します。

メール:

apexbiomass0909@gmail.com電話:[wa/line : +86- 18562307530]

もっと眺め

バイオマス ペレットミル機械産業の世界市場展望

2025-12-24

.gtr-container-x7y2z9 {

font-family: Verdana, Helvetica, "Times New Roman", Arial, sans-serif;

color: #333;

line-height: 1.6;

padding: 15px;

box-sizing: border-box;

width: 100%;

max-width: 100%;

overflow-x: hidden;

}

.gtr-container-x7y2z9-title {

font-size: 18px;

font-weight: bold;

margin-bottom: 20px;

text-align: left;

color: #0056b3;

}

.gtr-container-x7y2z9 p {

font-size: 14px;

margin-bottom: 15px;

text-align: left !important;

line-height: 1.6;

color: #444;

}

.gtr-container-x7y2z9 p:last-child {

margin-bottom: 0;

}

.gtr-container-x7y2z9 strong {

font-weight: bold;

color: #000;

}

@media (min-width: 768px) {

.gtr-container-x7y2z9 {

padding: 30px;

}

.gtr-container-x7y2z9-title {

margin-bottom: 25px;

}

.gtr-container-x7y2z9 p {

margin-bottom: 20px;

}

}

バイオマス ペレットミル機械産業の世界市場展望

の世界市場は、バイオマス ペレットミル機械再生可能エネルギー政策とエネルギーコストの上昇を背景に、着実に成長しています。ヨーロッパは最大のペレット消費地域であり、北米とアジア太平洋市場は急速に拡大しています。

輸出志向のペレットプラントは、国際的な品質基準を満たすために、大容量のバイオマス ペレットミル機械に依存しています。ペレットの耐久性、水分含有量、サイズの一貫性は、国際貿易にとって重要な要素です。

メーカーは、原材料の種類、生産能力、地域のエネルギー規制に基づいて、ますますカスタマイズされたソリューションを提供しています。この柔軟性により、バイオマス ペレット設備は多様な市場ニーズに適応できます。

世界中で再生可能エネルギーへの投資が増加するにつれて、バイオマス ペレットミル機械は、持続可能なエネルギー生産と環境保護を支える重要な技術であり続けると予想されます。

もっと眺め

バイオマスのペレットミール機械は,クリーンな加熱燃料の需要を増加させる

2025-12-24

バイオマス ペレットミル機がクリーン暖房燃料の需要増加を支える

クリーン暖房燃料の需要は、特にヨーロッパと北米で増加し続けています。バイオマス ペレットミル機 は、大規模なペレット生産を可能にすることで、この需要に応える上で中心的な役割を果たしています。

バイオマス ペレットは、家庭用ペレットストーブ、地域暖房システム、および工業用ボイラーで広く使用されています。その均一なサイズと高密度により、自動供給と効率的な燃焼が可能になります。

工業用向けに設計されたペレットミルは、ダウンタイムを最小限に抑え、24時間365日稼働できます。冷却システム、集塵機、ペレット選別装置などが、完全な生産ラインに統合されることがよくあります。

石炭や化石燃料の使用に対する規制が強化される中、バイオマス ペレットは好ましい代替燃料になりつつあります。その結果、バイオマス ペレットミル機への投資は、世界市場全体で増加し続けています。

もっと眺め

技術的進歩がバイオマス・ペレットミル機の効率を向上させる

2025-12-24

技術革新がバイオマス・ペレットミル機の効率を向上

近年、継続的なイノベーションにより、バイオマス・ペレットミル機の性能が著しく向上しました。メーカーは現在、出力の増加、エネルギー消費量の削減、および機器の寿命延長に注力しています。

主な進歩の一つは、ダイスとローラーに高強度合金鋼を使用することです。これにより耐摩耗性が向上し、機械が長期間にわたって高負荷で動作できるようになります。自動潤滑システムは、メンテナンス要件をさらに削減します。

インテリジェント制御システムも標準装備となりました。オペレーターは、温度、圧力、モーター負荷をリアルタイムで監視し、安定した運転と一貫したペレット品質を確保できます。これらのシステムは、ダウンタイムを削減し、全体的な生産効率を向上させます。

エネルギー効率ももう一つの重要な改善点です。最適化された伝送システムと可変周波数ドライブは、ペレット1トンあたりの消費電力を削減するのに役立ちます。

これらの革新のおかげで、バイオマス・ペレットミル機は現在、より信頼性が高く、費用対効果が高くなっており、大規模な工業プラントと中規模のバイオマス事業の両方に適しています。

もっと眺め

バイオマスのペレット ミル 機械 が 農業 廃棄物 の リサイクル に 必要 な 理由

2025-12-24

バイオマスのペレット ミル 機械 が 農業 廃棄物 の リサイクル に 必要 な 理由

農業廃棄物の管理は世界的に大きな課題となっていますバイオマスのペレットミール農作物残留物を価値のある再生可能燃料に変換することで 効果的な解決策を提供します

バイオマスのペレットミールマシンを使用して, バイオマスのペレットミールマシンを使って,これらの材料は,工業用や住宅用暖房用に適したバイオマスペレットに加工できます.

ペレティゼーションは材料の容量を減少させ エネルギー密度を増加させ,輸送と貯蔵を効率化し,環境汚染を削減します.農家やバイオマスの加工業者は,廃棄物を販売可能な製品に変換することで,追加の収入を得ることができます..

先進的なバイオマスのペレットミール機械は 変動する水分含有量と混合した原材料を処理するように設計されています強化されたロールと最適化された模具設計は,困難な農業バイオマスの加工でも安定したペレット形成を保証します.

循環経済モデルへの関心が高まりつつあり,バイオマスペレット生産は農業と再生可能エネルギー産業の重要なリンクになっています.

もっと眺め